Perfect packaging hinges on precise box measurements. Whether you're shipping products, moving items, or storing goods, accurate measurements ensure safety, cost-efficiency, and customer satisfaction. This guide delves into the essentials of box measurements, providing detailed insights for mastering this crucial aspect of packaging.

Understanding Box Dimensions

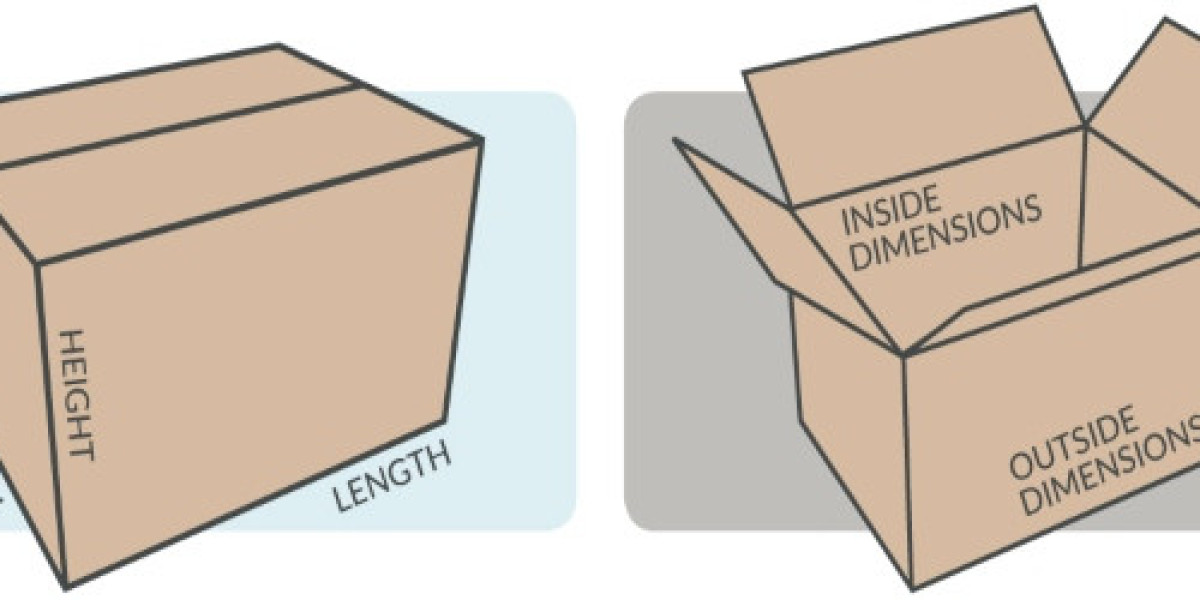

Box dimensions are the foundation of effective packaging. When measuring a box, it's important to consider three key dimensions: length, width, and height. Length is the longest side of the box, width is the side perpendicular to the length, and height is the vertical dimension from the base to the top. These measurements are crucial for determining the volume and fitting the contents appropriately.

When you measure a box, always measure from the inside to account for the thickness of the box walls. This ensures that the internal dimensions, which are the most important for fitting your items, are accurate. External box with dimensions can be used when planning for storage or shipping space requirements. Understanding these basics will help in selecting or designing the right box for any purpose.

Choosing the Right Box Size

Selecting the right box size is critical to ensuring your items are protected and efficiently packed. A box that is too small may not adequately protect the contents, while an oversized box can lead to wasted space and higher shipping costs. To choose the right box size, start by measuring the items you need to pack. Ensure there is enough room for cushioning materials like bubble wrap, foam peanuts, or paper padding.

Consider the nature of the items as well. Fragile items require more padding and thus a slightly larger box. Heavy items need sturdy boxes with reinforced walls to prevent them from breaking through. The goal is to balance protection with efficient space usage. Once you have your measurements, look for standard box sizes that closely match your requirements to save on custom box costs.

Importance of Accurate Measurements in Shipping

Accurate measurements are vital for shipping efficiency and cost management. Shipping companies calculate fees based on the dimensional weight, which combines the size and actual weight of the package. Incorrect measurements can lead to unexpected charges and potential delays. Ensuring precise box measurements helps avoid these issues and keeps shipping costs predictable.

Additionally, correct measurements prevent damage during transit. Boxes that are too small may not offer adequate protection, while oversized boxes can shift during shipping, leading to damaged goods. Accurate measurements ensure the right amount of packing material is used, providing a balance between protection and cost.

Tools for Measuring Boxes

Several tools can help you measure boxes accurately. A tape measure is a basic yet essential tool. For more precise measurements, especially in a professional setting, consider using a caliper. Calipers can measure internal dimensions with high accuracy, ensuring that your box measurements are precise.

Digital measuring tools are also available. Laser distance measurers provide quick and accurate readings, useful for large-scale operations. These tools can save time and reduce human error. Additionally, box measuring software can assist in calculating dimensions, volume, and even suggesting the best box size based on your input measurements.

Common Measurement Mistakes

Despite the best intentions, measurement mistakes are common. One frequent error is measuring from the outside of the box rather than the inside. This mistake can lead to boxes that are too small for the intended contents. Always measure from the interior to get the most accurate dimensions.

Another common mistake is not accounting for the thickness of the packaging material. This oversight can result in boxes that don't fit as expected. Always include the material thickness in your calculations to ensure a proper fit. Additionally, failing to measure irregularly shaped items accurately can lead to poor packaging choices. Take your time to measure all dimensions carefully, including protrusions or unusual shapes.

Optimizing Packaging for Cost Efficiency

Cost efficiency in packaging goes beyond just box size. It includes material selection, packing methods, and optimizing the entire process. Start by choosing the right box size to reduce excess space and materials. Smaller boxes are not only cheaper but also require less filler material.

Consider using recycled or eco-friendly materials. These can be cost-effective and appeal to environmentally conscious consumers. Bulk purchasing of packaging materials can also lead to significant savings. Negotiating with suppliers for better rates on large orders can help reduce costs.

Sustainable Packaging Practices

Sustainability is increasingly important in packaging. Consumers and businesses alike are focusing on reducing their environmental impact. Sustainable packaging practices not only benefit the environment but can also lead to cost savings and improved brand image.

Start by choosing recyclable or biodegradable materials. Many packaging suppliers offer eco-friendly options that provide adequate protection without harming the environment. Reducing the size of your packaging can also contribute to sustainability by minimizing material usage and reducing shipping emissions.

Testing and Quality Control

Ensuring the quality and accuracy of your packaging involves thorough testing and quality control measures. Testing your packaging under real-world conditions helps identify potential weaknesses and areas for improvement. Drop tests, compression tests, and environmental testing are common methods to evaluate packaging performance.

Implement a quality control process to regularly check the accuracy of your box measurements and the quality of materials used. This includes inspecting incoming materials from suppliers and ensuring that all packaging meets your specifications. Regular audits and checks can help maintain high standards and catch issues before they become major problems.

Future Trends in Packaging

The packaging industry is constantly evolving, with new trends and technologies shaping its future. One significant trend is the increasing use of smart packaging. This includes packaging embedded with sensors or RFID tags that provide real-time information about the product’s condition and location. Smart packaging can improve supply chain efficiency and enhance the customer experience.

Another trend is the move towards more sustainable materials. Innovations in biodegradable plastics and compostable materials are reducing the environmental impact of packaging. Companies are also exploring new designs that use less material without compromising protection.

Conclusion

Mastering box measurements is essential for effective packaging. From understanding basic dimensions to choosing the right box size and implementing sustainable practices, every step plays a critical role in ensuring your packaging meets its purpose efficiently and cost-effectively. By following the guidelines and utilizing the tools and tips provided in this guide, you can achieve perfect packaging for your needs.