Nice — here’s a compact, ready-to-use market reference for the Battery Recycling market with a short company reference list (company → value / positioning) plus the structured analysis you requested. I checked recent market reports, vendor sites and trade press so the load-bearing facts below are sourced.

This versatile research report is presenting crucial details on market relevant information, harping on ample minute details encompassing a multi-dimensional market that collectively maneuver growth in the global Battery Recycling market.

This holistic report presented by the report is also determined to cater to all the market specific information and a take on business analysis and key growth steering best industry practices that optimize million-dollar opportunities amidst staggering competition in Battery Recycling market.

Read complete report at: https://www.thebrainyinsights.com/report/battery-recycling-market-13480

Quick market snapshot (consensus)

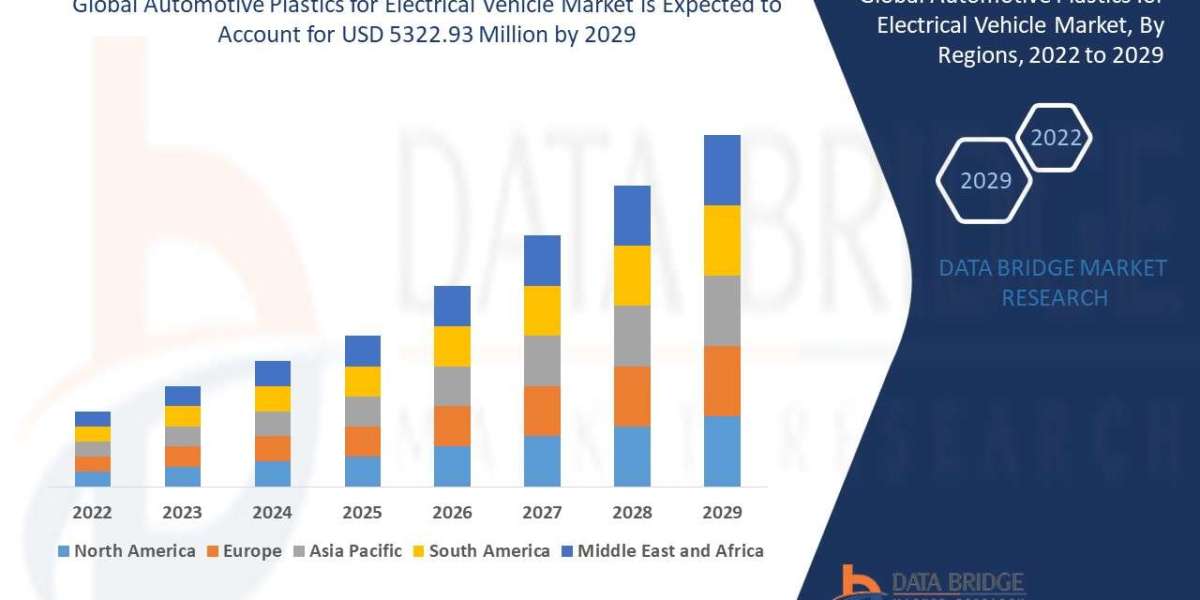

Reported market-size ranges differ by vendor and scope (some include all battery types, others only Li-ion/EoL EV batteries). Example estimates: ~USD 26–36B in the mid-2020s with double-digit CAGR forecasts into the late 2020s/2030 depending on source and definition (MarketsandMarkets, DataBridge, Grand View show differing bases and CAGRs).

Top companies — reference list + short “values / positioning”

(representative global players, mix of hydrometallurgical, pyrometallurgical, direct/up-cycling and second-life operators)

Redwood Materials (USA) — large U.S. recycler & materials company focused on closed-loop recovery of Li, Ni, Co, Cu and also on second-life energy storage (strong vertical integration and U.S. domestic supply positioning).

Li-Cycle / Glencore Battery Recycling (Canada → now part of Glencore) — hydrometallurgical “black-mass” processing specialist that scaled quickly via modular hubs and spoke plants; recently acquired/rolled into Glencore’s recycling business (larger trading/mining backing).

Umicore (Belgium) — established materials-recovery and cathode-materials business with industrial recycling plants and integrated recovery → refines and produces battery-ready cathode materials (strong Europe/industrial positioning).

Fortum Battery Recycling / Hydrovolt (Nordics) — regional partners focused on battery production waste and EV battery recycling in the Nordics, integrating mechanical pretreatment and material recovery for European supply chains.

American Battery Technology Company (ABTC) / American Manganese / RecycLiCo (North America) — specialty hydrometallurgical developers with pilot-to-commercial projects focused on recovering Li, Ni, Co and upgrading black mass into battery-ready materials.

Duesenfeld (Germany) — mechanical / direct / low-temperature process specialist offering direct cathode scrap recycling and upcycling solutions (focus on low-energy, less chemical-intensive routes).

Large commodity / trading groups (Glencore, Umicore, etc.) and regional specialists (Hydrovolt, Ecobat, East Penn) — influence supply via ore/metal trading, smelter/refinery capacity or regionally focused battery recycling services.

Note: many other regional and tech-specialist firms exist (small hydromet startups, electronics recyclers adapting to EV black mass). For precise revenue/market-share splits you’ll typically need paid datasets or company filings.

Recent developments

Large capital raises and capacity expansion (e.g., Redwood raising recent funding and expanding second-life + recycling capacity) reflecting investor interest in domestic critical-material supply.

M&A and industry consolidation — large miners/traders moving into recycling (notably Li-Cycle joining Glencore), accelerating scale and integrating recycling with trading/refining.

Cooperation across the value chain (battery makers, OEMs and recyclers partnering— e.g., Hydrovolt ↔ Fortum collaborations) to secure feedstock and closed-loop supply.

Drivers

Rapid growth of EV parc & battery retirements — rising volumes of end-of-life EV batteries produce feedstock (black mass).

Policy & regulation pushing circularity (EU battery regulation, national recycling mandates) and securing domestic critical materials.

High critical-metal prices & supply security concerns (need to reduce dependence on mined imports for Li/Ni/Co).

Restraints

Feedstock logistics and cost (collecting, transporting, safe handling of EV packs and modules is complex and expensive).

Technology & economics variability — hydrometallurgy, pyrometallurgy and direct/upcycling have different CAPEX/OPEX and varying recovery rates; no one method is dominant yet for all battery types.

Regulatory/safety hurdles for handling damaged batteries (fire risk) and local permitting for recycling plants.

Regional segmentation analysis

Asia-Pacific (China, Korea, Japan) — large existing recycling capacity for portable and industrial batteries; China remains a dominant recycler/refiner of battery metals.

North America — rapid capacity build (Redwood, Li-Cycle hubs, ABTC pilots), policy push for domestic supply chains → big growth focus.

Europe — strong regulatory push (EU battery rules) and industrial players (Umicore, Fortum/Hydrovolt, Duesenfeld) focusing on mechanical + hydromet routes.

Emerging trends

“Second-life” pathways vs full recycling — repurposing EV packs for stationary storage (microgrids/energy storage) where capacity allows, reducing immediate recycling volumes and adding value. Redwood’s second-life microgrid work is a clear example.

Direct / low-energy “upcycling” processes (to keep cathode crystal structure, avoid full raw-material separations) — pilot projects in Europe (Duesenfeld) and elsewhere.

Modular hub-and-spoke models (pre-treatment near collection, centralized hydromet hubs for chemistry) to lower transport costs and increase throughput (used by Li-Cycle & others).

Top use cases

Recovery of Li, Ni, Co, Cu, Mn from end-of-life EV batteries → battery-grade materials for new cathodes.

Recycling production scrap / manufacturing scrap (direct recycling/upcycling into battery-ready material).

Second-life stationary storage systems built from retired EV packs (defer recycling and extract additional value).

Major challenges

Quality of recovered materials (battery-ready specs) — recyclates must meet high purity and morphological specs for cathode production.

Scaling economics — achieving throughput & recovery rates that make operations profitable vs volatile commodity prices.

Standardisation & traceability — battery chemistries and formats vary widely (LFP vs NMC vs NCA), complicating optimal processing routes.

Attractive opportunities

Industrial-scale hydrometallurgical hubs capable of producing battery-grade cathode precursors domestically (reduces supply-chain vulnerability).

Services around safe collection, pack disassembly and logistics (front-end de-energising / BMS data capture services) — high value given fire risk and regulatory needs.

Upcycling/direct recycling for higher value retention (returning cathode active material in near-battery-ready form)

Key factors of market expansion

EV fleet growth and retiring-battery volumes — volume feedstock is the primary long-term driver.

Favourable regulation & minimum recycling targets (e.g., EU battery regulation) and government incentives for domestic value-chains.

Technological progress improving recovery yields and reducing costs (better hydromet flowsheets, direct recycling methods).